Comfort

Ensuring Safety and Comfort

Since social infrastructure is the foundation of our lives and economy, its maintenance is essential.

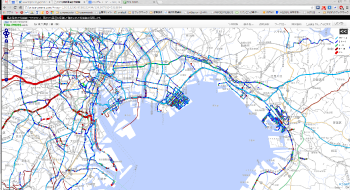

We offer strategic road maintenance plans that integrate pavement maintenance techniques (planning, inspection/diagnosis, performance evaluation/forecasting, maintenance/rehabilitation design, etc.) with asset management.

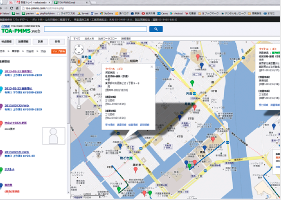

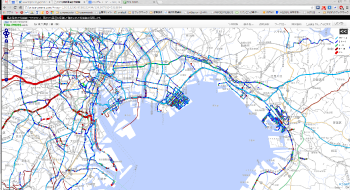

TOA-PMMS (Pavement Maintenance Management System)

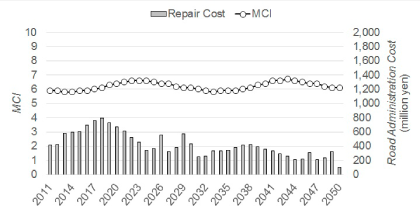

Toa Road Corporation has been providing pavement maintenance and management system “TOA-PMMS” for strategic and efficient management of road asset, resources and budget. The feature of management system in TOA-PMMS is turning PDCA cycle shown below. The reliability of PMMS is improved by implementing ex-post/performance evaluation and reestablishing management objective in the cycle.

Design (Do)

Design for maintenance and rehabilitation

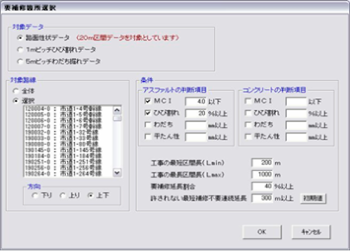

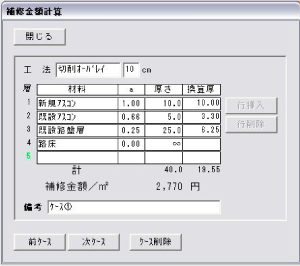

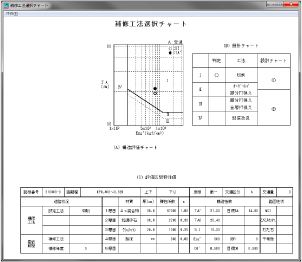

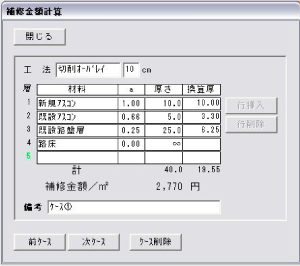

Based on pavement management plan and evaluation result, the pavement structure for the section to be repaired is designed. Comparing selected result, rehabilitation plan will be decided either major (extended length) rehabilitation at long distance or small (partial) rehabilitation to severely damaged section. At the sections with low priority for rehabilitation, it is examined if there is any section to be maintained at this stage.

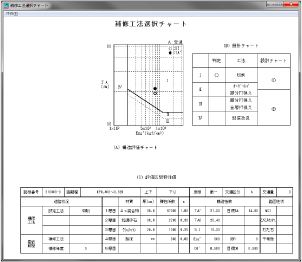

Examine pavement structure and method for rehabilitation

Based on damaged conditions and result of strength/bearing capacity evaluation, rehabilitation plan and method is decided. According to evaluation result from FWD and excavation survey, pavement structure for rehabilitation is designed. Compare cost of various type of repaired pavement structure, finally appropriate rehabilitation method and its structure is decided .

Result of evaluating bearing capacity at surveyed point

Design of pavement structure for rehabilitation

Check

The evaluation of existing pavement is to survey how and why the required pavement performance / function was degraded and to evaluate based on several indices.

1. Survey of pavement surface and riding comfort

- CHASPA

CHASPA surveys pavement surface profiles required for strategic management accurately and promptly. It measures surface characteristics as cracking, rutting and smoothness simultaneously. Also, specific feature of our CHASPA is to take photograph of pavement surface in front at even intervals and to measure International Roughness Index (IRI) and Mean Profile Depth (MPD) which is index of pavement surface texture.

- Measurement of pavement surface profiles using smartphone

Install smartphone to any car and measure IRI and smoothness of pavement surface by embedded sensor while traveling. At the same time, take pavement surface photograph by action camera. It can obtain accurate surface profiles as existing high accurate pavement surface profiler.

2. Surveying pavement soundness

- FWD (Falling Weight Deflectometer)

A weight is dropped onto the loading plate on the existing pavement surface and measures resulted impact load and deflection volume at that time. Deflection volume varies depends on structural strength of each layer, therefore, by backcalculating deflection, elastic modulus can be estimated and bearing capacity of subgrade is evaluated. Also, FWD can be applied to evaluate bridge deck and pavement performance by loading a weight on the bridge deck.

- HFWD (Handy FWD)

HFWD measures load and deflection volume of subgrade and base course by dropping a weight, then, calculate elastic modulus and reaction coefficient of the ground to evaluate subgrade and base course.

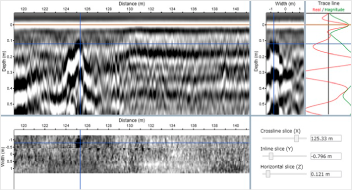

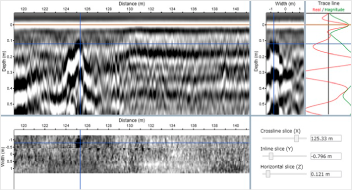

- 3D-Radar (Ground Penetration Radar)

3D-Radar effectively surveys underground information non-destructive. Utilizing transmission, reflection and refraction of electromagnetic waves, it creates visible image of the boundary surfaces of different materials (dielectric constant).

Analysis (Action)

Analysis is to calculate and evaluate pavement soundness based on surveyed data. It includes updating of Database.

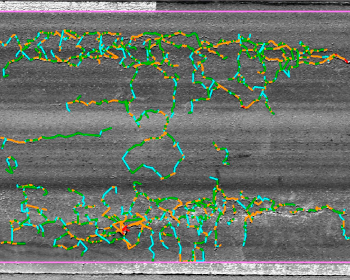

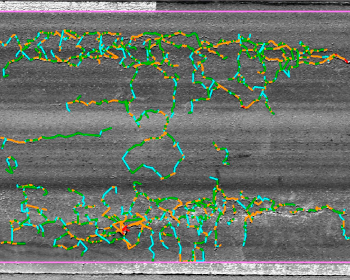

Analysis diagram of cracking

Analysis of electromagnetic wave

Analysis of IRI from measured data